Erdenet Cashmere

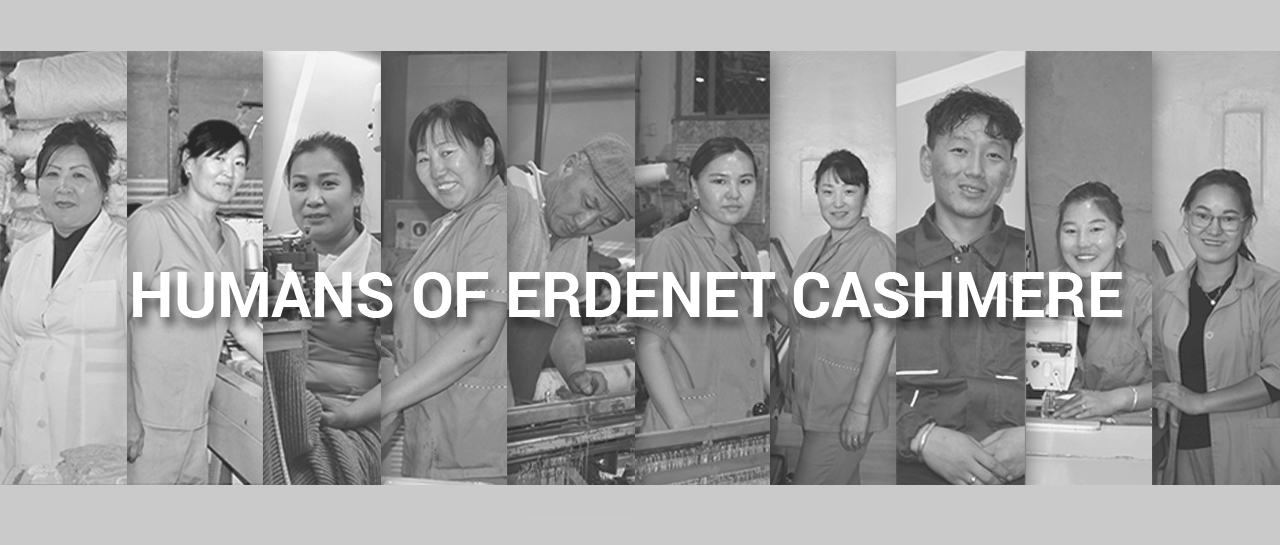

I first started working for the factory in July of 2017. Originally coming from Selenge province with two spare changes of clothes, I interviewed with the company and was immediately given the privilege to work knitting and weaving cashmere. I started this line of work learning from my teacher E. Batbayar. His mastery of the techniques and technology involved intrigued and guided me. Since working here, I have been creating my memories by executing each step and process as well-organized and cooperatively as possible. For the workers in the past, present and future, I would like to say thank you and good luck for creating something so huge. For those of the future generations, I would like to say live your life with a purpose and a goal. You will be rewarded for the pursuit of your dreams.

I initially started working for Erdenet Cashmere in the slippers department, but vividly remember being compelled to work with the automated pattern machines. 3 years into my employment for the factory, they gave me the opportunity to do so. Achieving something that I wanted from the beginning gives me a lot of happiness and motivation to continue working harder. Attaining what I wanted from the start showed my family and my children the things that are possible in life through hard work and persistence.

As a child, I was always fascinated with the Russian “adial” and wondered how they make them so soft and comfortable. My interest in the machinery and the process therefore stems from my childhood memories and interests. Working in Erdenet Cashmere’s factory for over 10 years, I have learned a lot about the process that goes into creating cashmere as well as the machinery involved. Although it took time and hard work, I learned that trial and error is crucial in mastering anything. During my time off, I enjoy hand crafting. My involvement in creating something demands organization and clarity in anything that I am doing; which is what I suggest for those after me.

I have always been interested in the mechanics of things, and fixing them. I initially entered Erdenet Cashmere in 2006 as a guard for the factory. They provided me with the opportunity to sit in classes for repairing broken or faulty machinery. Ever since 2007, I began working as a repairman for the factory and I am extremely thankful for it. To improve my skills and knowledge of my work, I spend my spare time woodworking. Working for Erdenet Cashmere has given me a lot of memories with my coworkers. I have appreciated all the opportunities I have been given, and continue to better myself. I try my best to work effectively and efficiently to provide my employers with the best results.

As a sewer, I always put a lot of effort into each piece I sew. Seeing the final results gives me a lot of pride, which is why I always try to improve and hone my skills. I truly believe in finishing whatever you started, and try to do so to the best of my abilities. I really appreciate what I do at this factory and hope that it makes a difference for Erdenet Cashmere.

I started working for Erdenet Cashmere early 2017. As soon as I started working, I immediately understood the demands of not only this job, but the dedication and effort that goes into being successful at anything. I remember spending multiple nights in the factory. I am a big believer in finishing what I started, and this is what drove me to become adept in my abilities as a knitter at the factory. I make my best effort everyday to be as productive as I can during my 8 hour shift.

Working for Erdenet Cashmere has given me the opportunity to meet a lot of new incredible people. The year that I have worked here, my coworkers have truly created an exciting and enjoyable work culture. I have always been fond of knitting and creating things with my own hands, and have 16 years of experience in it, so it is a privilege do be doing something that I am passionate about. Even in my free time, I like to sew whatever I can on my sewing machine for my family. Learn to enjoy the things you are doing, and execute them with joy and pride.

My involvement in smaller wool and cashmere factories led me to apply for a major manufacturer like Erdenet Cashmere. I started as a factory worker in 2018 and have dedicated my time to mastering my abilities in the factory. The other employees at the factory were extremely welcoming and I have appreciated the time we have spent together both at work and outside of the factory. I think it is important to work as a team with your cowokers because we all have the same pursuit and goa. The time I spend outside of the factory, I make use of by spending it with my family. I value the time I devote to the things I am passionate about, and I think that it is a key factory to success and happiness.

I first started working for the factory in 1986 when it was still known as “Erdenet Carpet LLC.” 35 years later, I still am passionate about my contributions to the company now known as “Erdenet Cashmere LLC.” I was first fascinated by the operations of each machinery in the factory and continue to be today. A large portion of my adulthood has been spent in this factory for this company, therefore it holds a very precious place in my heart. I believe persistence is important in any venture. To future generations, I advise following the rules and regulations; and through determination, you will achieve your biggest goals.

Doing the thing you look is truly a blessing. I take joy in sewing because it gives me the freedom and immunity to do whatever I want. I first joined the factory in 2017 and I have appreciated every minute of it. The people I have met and gotten to know have become my motivation and inspiration to keep working harder and better. Supporting one another is crucial in life and I thank my coworkers to making my experience at Erdenet Cashmere easy and pleasurable.

A woven fabric is one that is produced in such a manner in which the threads transverse through one another perpendicularly to create both a base and a cross-thread.

Erdenet Cashmere has enough productive capacity to produce roughly 60,000 meters worth of woven fabrics in a single shift.

The woven fabrics in our factory is produced from either cashmere, yak wool or sheep’s wool to manufacture a wide selection of slippers, scarves, cloaks, blankets and other fabrics.

Our shuttle weaving machine(the Dobbi, mark 1515) has a mechanical capability that requires the cross wire to be switched out manually, and thus often disrupts stable production. On the other hand, our knitting machine (the Dornier, mark Itema machine), micro shuttle machine and STB weaving machine has an automated capability that has the faculty to automatically change its cross wires.

Clothing serves several functions for its consumers. Its ability to protect the body from outside or external forces while serving a purpose of functionality and style makes it an extremely important and diverse consumer product.

Erdenet Cashmere’s sewing plant have combing, weaving, cutting and inspecting processes; and has the capacity to produce 80,000 sewn products each year.

The sewing department of Erdenet Cashmere manufactures a wide range of products such as sewn blankets, bedding, pillows, pillowcases, sleeping mats, baby blankets, mattresses, and more. A majority of these products are made out of 100% sheep and camel wool, and are ensured high quality.

A fabric that is made through knitting is done so by forming a loop by bending the threads together. Knitted fabric is all created by one continuous thread. Erdenet Cashmere’s knitwear plant was commissioned in the second quarter of 2013 and has since had the stable capacity to produce 11,000 sweaters per year.

The knitwear factory produces a total of 10 types of products, from hats and scarves to sweater, dresses and pants. All of these products are produced from cashmere, yak wool and sheep wool.

Our knitwear plant has a total of 8 machines that all have the total capacity to complete finalized products from start to finish:

Four Stoll cms 530 HP multi gauge machines made in Germany

Four complete processing equipment made in China